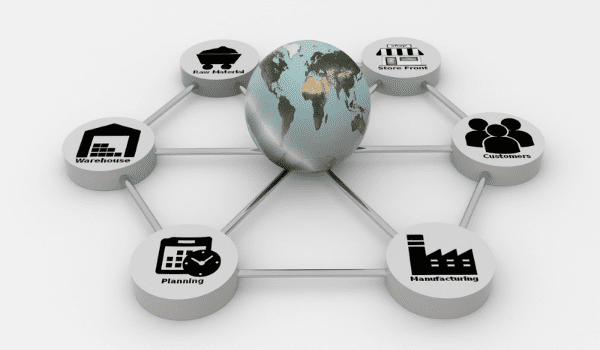

The Global Supply Chain in 2023

In today’s global supply chain, the transportation of perishable goods is a crucial part of many industries. One of the most significant challenges in transporting these goods is maintaining the temperature throughout the journey. Small fluctuations can have a severe impact on product quality as well as safety. To address this challenge, the concept of cold chain shipping has emerged as a critical component of the global supply chain.

The global supply chain is expected to grow significantly in the coming years. Moreover, driven by increasing demand, expanding pharmaceutical and healthcare industries, and the need for temperature-sensitive logistics in emerging markets. According to a report, the cold chain market is expected to reach $447.5 billion by 2025, growing at a CAGR of 7.6% from 2020 to 2025.

Optimization

One of the critical factors driving the growth of the cold chain market is to optimize shipping and inbound logistics to meet the increasing demand for fresh and frozen food products worldwide. With the rise in urbanization and changing consumer preferences, there is a growing demand for fresh, healthy, and convenient food products.

Meanwhile, this has led to a significant increase in the transportation of perishable food items such as fruits, vegetables, meat, and seafood. All of which require a stable temperature throughout the journey to maintain quality as well as safety.

In addition to food products, the pharmaceutical industry is also a significant user of cold storage warehouses. Many pharmaceutical products, including vaccines, blood products, and biologics, require a specific temperature range to maintain their efficacy and safety. The cold chain is critical to ensuring the quality of these products and preventing spoilage or degradation during transportation.

Management

Cold storage warehousing and logistics management also plays a crucial role in the global industry. Biotech products, including cell and gene therapies, require specific temperature conditions throughout the manufacturing and distribution process. Cold chain shipping is vital to ensuring that these products maintain their integrity and effectiveness during transport.

The cold chain shipping process typically involves several stages, including pre-cooling, loading, shipping services, and unloading. Pre-cooling involves preparing the product for transport while cooling it to the required temperature range.

The success of cold storage and distribution relies heavily on the coordination and collaboration of various stakeholders, including manufacturers, shippers, logistics providers, and regulatory agencies. Manufacturers are responsible for ensuring that their products meet the necessary temperature requirements and are properly packaged for transport.

Shippers as well as logistics providers are responsible for ensuring that the products are transported safely and efficiently. This includes proper temperature control and monitoring. Regulatory agencies, such as the FDA and USDA, are responsible for establishing guidelines and regulations to ensure the safety and efficacy of temperature-sensitive products.

Our Central Locations Make It Easy!

Interested in learning how to optimize your supply chain product or service? Reach out to our team today to see which of our logistics services best suits your unique chain model.

We Provide The Following Handling Needs

- Palletizing

- Re-Weighting

- Re-gelling

- Re-packaging

- Dry Storage

- Cold Storage space

- Cross-docking

- Quality Report Inspections

- Party logistics

Because of its close proximity to one of the largest airports in Texas, our cold storage logistics warehouse in Dallas is the perfect location for your frozen supply chain needs. From small business owners and entrepreneurs to large-scale manufacturers, our innovative logistics solutions help you run your business successfully.